PERTH DISTRIBUTOR

Wilkinson Suspension is the exclusive Perth-based distributor for King Springs Australia. We stock and install a wide range of King Springs products at our suspension workshop in Bayswater, WA. Are you looking to equip your vehicle with a set of King Springs? Get in touch for a quote! Give us a ring on (08) 9370 2646 or go to the Contact Page and fill out the enquiry form.

LEADER IN DESIGN AND DURABILITY

On the world’s fastest racetracks, on the street, on the toughest outback terrain there is. When it comes to spring design and durability, King Springs knows neither compromise nor second best. Design and durability are the cornerstones of King Springs spring technology and the reason why King Springs are leaders in the replacement and performance automotive spring market. All King Springs products are designed according to the highest quality and durability standards and are built with Australian road conditions in mind. King Springs are leaders in progressive rate coil spring technology. Both tapered wire and variable pitch are incorporated in many spring designs where necessary to gain maximum achievable benefit in ride comfort, handling and varying load carrying capacity.

WHY YOU NEED KING SPRINGS

Springs play an essential part in the performance, stability and handling of your vehicle and King Springs products are designed to achieve top-notch performance in terms of Height, Handling and Heavy Loading.

1. HEIGHT

There are a few main reasons to purchase springs that change the height of your vehicle: Vehicle lowering, maintaining of vehicle height/returning to standard height and vehicle raising. King Springs offers products for each of these purposes.

- VEHICLE LOWERING

The most popular reason to buy King Springs is to lower your ride. Here are some of the biggest benefits of lowering your vehicle:

Lower your vehicle’s centre of gravity

Let your car sit closer to the ground and increase your car’s stability in turns and various other maneuvers.

Increase Aerodynamics

If you decide to lower your ride, there will be a significant decrease in airflow moving underneath your vehicle. This can reduce the amount of drag imposed on the vehicle.

Cosmetic Enhancement

Lowered cars simply look great. Lowering your vehicle will add to the visual appeal of your car.

- MAINTAIN OR RETURN TO VEHICLE’S STANDARD HEIGHT

Another common reason to equip your vehicle with King Springs is to maintain or return back to standard vehicle height. When your vehicle’s springs are starting to sag, you can replace them with a new set King Springs to help your vehicle get back to its usual height. Alternatively, if you decide that previously fitted lowered springs are no longer required and you want to return your vehicle to its previous height, King Springs are perfectly suitable to achieve that.

- VEHICLE RAISING

This is a popular option that is most common for 4WDs, vehicles being used to carry heavy loads and towing vehicles. Whenever you require increased clearance from the road, this a good option. King Springs has a wide range of products to achieve this.

2. HANDLING

King Springs performance replacement springs will substantially improve vehicle handling and reduce body roll and improve your vehicle’s stability. King Springs performance lowered springs also lower your vehicle’s centre of gravity, which benefits overall handling.

3. HEAVY LOADING

All vehicles are manufactured to a generally acceptable standard and springs are no exception to this rule. With demands for comfort a growing priority, spring rates are kept as low as possible. For his reason, the original spring’s ability to carry load and tow etc is, in most cases, poor. King Springs performance replacement springs will decrease the vehicle’s ride height loss under load and improve vehicle stability when laden. King Springs performance replacement coil springs will achieve improvement in any or all of the above areas.

All Kings Springs Heavy Duty Replacement Springs are designed to be uprated. The degree of uprating varies between vehicles but can generally be stated at 20-40%.

The information and experience gained from our extensive involvement in motorsport only serves to enhance our ability to design and manufacture to the highest possible standards.

Manufacturing

MATERIAL

Only X5K material is used. X5K is a new generation High Strength Spring Steel which with-stands higher operating stresses and has superior resistance to sag, improved toughness and improved corrosion fatigue properties.

PEELING & TAPERING

Bar peeling and Tapering production line. Peels 1mm from the surface of the material removing any surface defects. Tapers up to 7mm from “parent” material. Peels diameter to any size, down from 24mm.

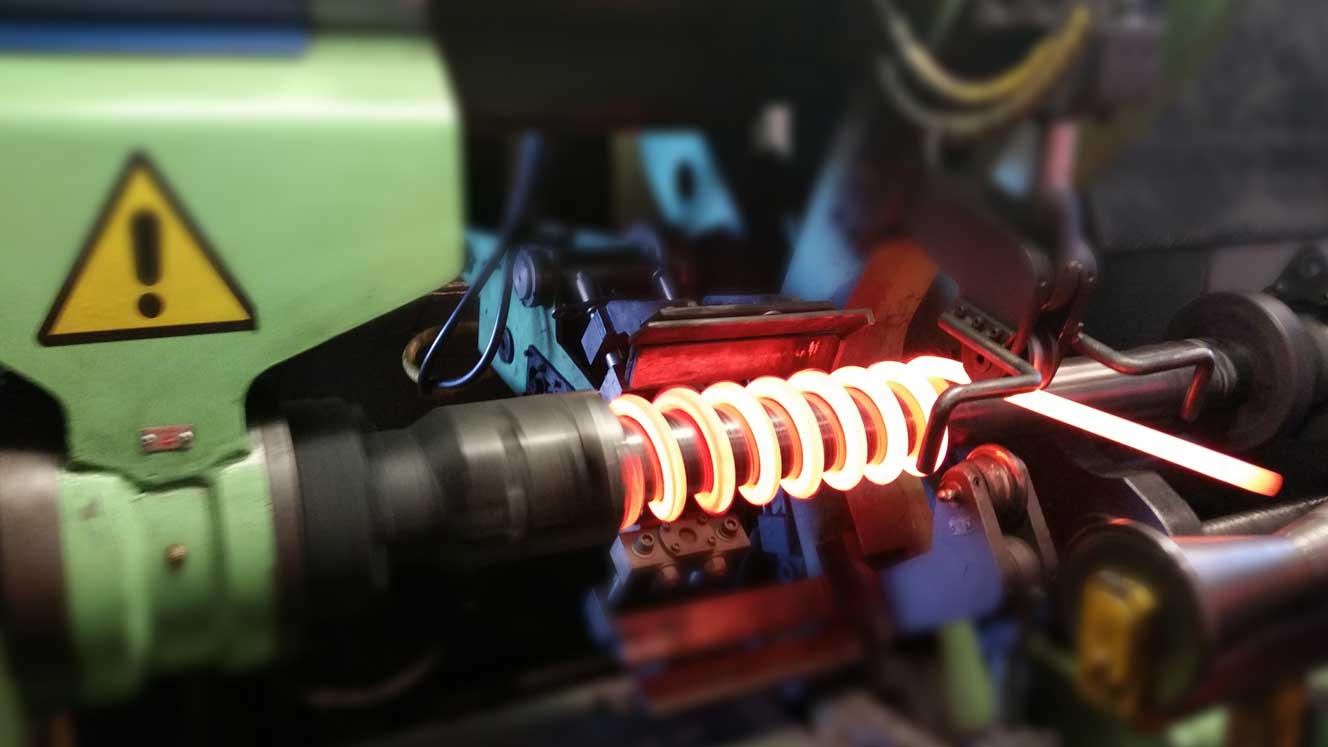

HEATING

Gas furnaces are used for their extremely clean and efficient heating properties. Coils are heated to around 1000 degrees Celsius before being rolled.

COILING

Computer controlled coilers are used to roll the coils whilst the bar is still over 950 degrees Celsius. Coilers have variable pitch speeds to manufacture the progressive pitch coils. Pitch has a tolerance of less than 1mm.

HARDENING

Once the coil is rolled it is then placed into the Quenching oil whilst still at 850 degrees Celsius and hardened to 62 HRC (Rockwell hardness)

TEMPERING

After the Hardening process the coil is then placed into the Tempering oven and heated back up to 400 degrees Celsius . Coil will be now tempered to a 54 HRC. This is done via a computer controlled and monitored gas furnace.

SPRING END GRINDING

Once the coil is tempered and if the coil design requires the coil to be ground square, then the coils are fitted into one of 5 Computer controlled wet grinders.

SHOT PEENING

The coil is now placed into our Conveyor fed shot peener and rotated for 100% coverage. This gives the coil a high intensity finish to ensure maximum fatigue life and an optimal surface for the powder coat to be applied to.

PRE-TREATMENT

Coil is now dipped with a phosphate coating for maximum corrosion protection.

POWDER COATING

Coils are now hung and sprayed with an Epoxy powder coat to achieve the most durable finish and offering maximum presentation.

KING SPRINGS HEIGHTS AND SIZES

Below is a generalised list of height options for King Springs products for your reference.

| KING SPRINGS L LOW | Lowering of 30mm |

| KING SPRINGS SL SUPER LOW | Lowering of 50mm |

| KING SPRINGS SSL SUPER LOW | Lowering of 60mm |

| KING SPRINGS SSSL SUPER LOW | Lowering of 70mm |

| KING SPRINGS STANDARD | Standard Height + Raising of 10mm |

| KING SPRINGS RAISED | Raising of 20-30mm |

KING SPRINGS CATALOGUE

Want to look up specific springs and parts for your vehicle? Download the catalogue below to find the products you need and call us for a quote!